| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

TUROMAK MAKİNA SAN. VE TİC. LTD. ŞTİ.

Kozyatağı Mah. Gülbahar Sok. No: 13/10 / Kadıköy / İSTANBUL / TÜRKİYE

|

Contact Info: +90 216 266 6612

|

Hall: 12

Stand: 1208/B

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Turomak Makina has been established in 2019 to provide sales of machine tools , consultancy and technical services. Our founders are aiming to continue sharing their extensive experiences which they have gained since over 40 years. Our company is an agency for the investment products such as; CNC Machine Tools (lathes, milling machines, machining centres, boring and drilling machines, grinding amchines etc.), Machines for Railway Systems, CNC Sheet Metal Working Machines (cutting, bending, drilling, shotblasting, painting). Moreover, Turomak is importing and selling electromagnetic handling systems, consumables, metal coating under vacuum and other industrial equipments. Turomak undertakes the representation, sales, consultancy and technical services of more than 20 companies, each of which is a leader in its field globally. The company is working with different producers located in Germany, Netherlands, Italy, Poland, Czech Republic, Hungary, China and Taiwan for a long time. Our company delivers its services mainly to Turkey as well as neighboring countries and different countries. After-sales installation, technical support with warranty and without warranty needs are handled by experienced technicians working within Turomak. Company also provides spare parts and consumables in case of requirements. The Company considers his customers as business partners and shares his experience from consultancy point of view. The main sectors of which Turomak Makina serves are as follows · General and Heavy Engineering Industry · Railway Industry · Iron & Steel Industry · Foundries · Energy Sector · Defense Industry · Aviation Industry · Mould & Dies Industry · Automotive Industry · Forging Industry · Ship Building Industry · Structural Steel Industry · Steel Construction Manufacturing Industry · Prefabricated Construction Manufacturing Industry · Construction Industry · Construction Beam Production Lines · Welding Automation Systems · Pressure Vessels Manufacturing Industry · Pipe Lines, Piping Systems · Special Purpose Welded Manufacturing · Automatic Profile Rolling / Special Profile Industry

No product info found.

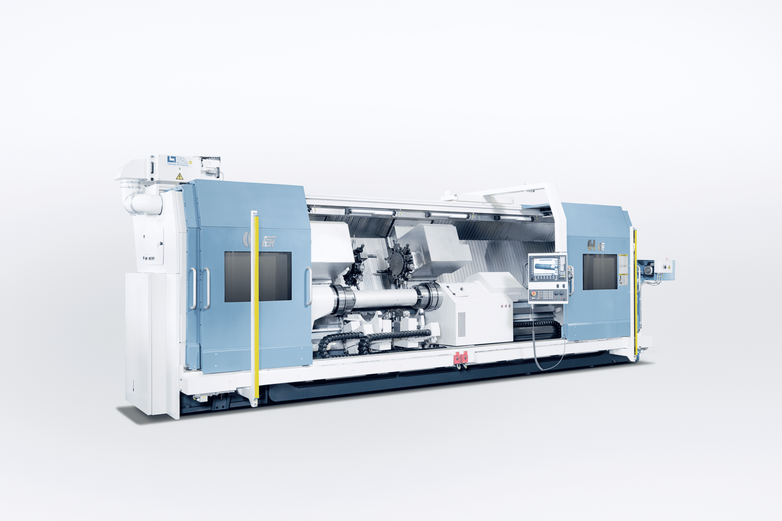

ABOUT US RAFAMET S.A. in Kuźnia Raciborska, Poland manufactures special-purpose machine tools for wheelset machining and is one of the leaders on the global market. RAFAMET is also a widely recognized and respected supplier of heavy-duty special-purpose machine tools for the customers in the machine-building, power generation, metallurgical, shipbuilding, and defense industries. The company has manufactured and sold over 5,500 machines for railways and over 750 other heavy-duty special-purpose machine tools to customers from almost 90 countries around the world. The share of export in total sales is 70-80%.

Solving productivity issues has always been our strength right from the start of our family business in 1973. How can we make manufacturing processes more efficient? was a question founder Bart van Ruth regularly asked himself. In our early years as an engineering company, we developed a range of machines for automating production processes which, until then, were mostly done manually. This resulted in our first CNC machine in the early 1980s. That moment, together with the introduction of that machine in the German market via an agent, proved to be the inspiration we needed to take our company to the next level.

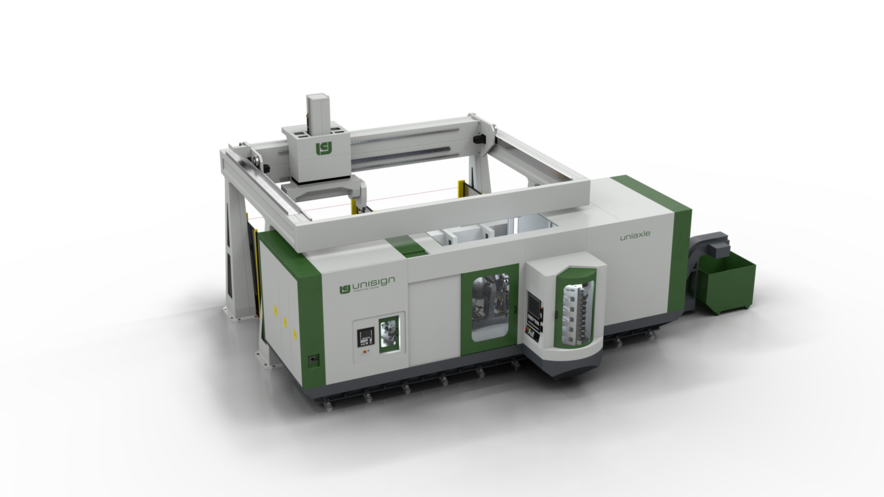

Our company operates on a total area of over 10,000 square meters. Our main activities include machine manufacturing, particularly CNC portal milling machines and carousel lathes, where we possess 60 years of experience and market-leading expertise. In addition to manufacturing new machines, we also modernize used machines and equip them with the latest technologies to make our clients production processes faster and more cost-effective. We have extensive experience in custom machine manufacturing, ranging from mining machinery to flame cutting machines and various conveyor systems. Alongside our machine manufacturing division, we also have machining and welding divisions. We work with more than 25 machining tools and excellent, certified welders. All three of our divisions serve our customers with excellent quality and precision. We manufacture CNC-controlled portal milling machines with table sizes ranging from 2x4 meters to 5x20 meters, and carousel lathes with rotary table sizes ranging from 2 meters to 5 meters. Our reference list includes renowned companies from both Europe and beyond. It can be said that we produce based on unique customer needs, with flexibility and at more favorable prices than our competitors. MZ Portal Machines MZP Portal Machines MZPG Portal Machines MZPH Machines MTT Carousel Machines

No product info found.

ESAB is a world leader in welding and cutting equipment and consumables. Our innovative, world-renowned equipment and fabrication technology solutions are developed with input from our customers and built with the expertise and heritage of a global manufacturing leader. Our collective vision is to transform the industry and meet our customers needs through our diverse portfolio of products.

OMSG was established in 1961 and since that time has proved itself to be a world leader in the design and manufacture of shot blast, shot-peening and machine systems. The group consists of four companies and four plants. In addition to the two offices of Italian Villa Cortese (headquarters of over 20,000 m2) and Dairago, both in the province of Milan, there are seats in Oullins Cedex France OMSG French and German OMSG Deutschland GmbH in Metzingen, near Stuttgart. Carlo Banfi - OMSG groupStarting from June 2017, OMSG group acquired the historical company CARLO BANFI that, starting from 1938, have installed more than 4,000 shot blasting machines worldwide. With such acquisition, OMSG group consolidates its position at international level, at same level with leading multinationals Companies and increase their presence in markets where CARLO BANFI was very active and popular. OMSG group is present worldwide with more than 5,500 shot blast machines installed in 86 Countries. Thanks to its Commercial network, consisting of more than 50 agents and distributors, and the after sales service and spare parts warehouses, we can ensure a quick and timely service worldwide. The range of our products is very large and serves several fields of industries including: foundries of ferrous and non-ferrous metals, steel structural works, aluminum die- castings, forge, draw-plates, galvanizing treatment, hot forming and cold, particular in the oil & gas, liquid and compressed gas cylinders, etc. OMSG group manufactures about 100-110 blast machines per year, of which 75% is bound for the export market, mainly Europe, North and South Africa, North and South America and the Middle East. OMSG group offers a wide range of standard shot blasting machines, more than 120 types on the price list including Tumblast blast machine Tappeto Rampante® either with rubber or steel conveyors, shot blasting machine with roller conveyors, Spinner hanger machines with hooks or hoists, tunnelblast machines, continuous belts and machines with Diabolo rollers, rotary tables, wire or bars. More than half of the production, however, is made up of special blast machines tailor-made to customer s requirements. All our shot blast machines are CE marked. All our machines and systems are certified according to ISO 9001 Quality. OMSG group cares particularly to the safety of its systems, users and their employees and workers. For this reason, since December 2015, we are certified in accordance to the Health and Safety of workers BS OHSAS 18001.

Faccin S.p.A. is one of the world leaders in the design, manufacturing and sale of plate and angle rolls, dished heads machinery and special machines. With a technologically advanced production and certified UNI EN ISO 9001:2015, Faccin is the largest production facility in the world of bending systems and plate bending machines. Through an extensive network of subsidiaries, Faccin provides thorough sales and after-sales service worldwide.

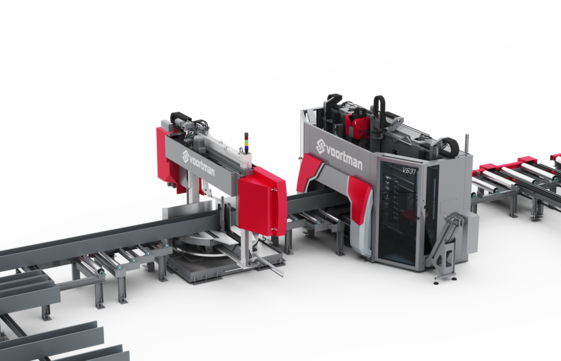

Welcome to Voortman Steel Machinery, a name synonymous with innovation, excellence, and a deep commitment to quality. We have grown from modest beginnings into a large global leader, creating unparalleled CNC steel processing machinery with integrated business software solutions that automate and optimize your production process.

Our business is the design, production and sales of permanent electro-magnetic systems for industry. The headquarters are in Italy, close to Milan. We have branches in USA, Germany, France and China, active commercially and with post-sales support. A network of importers and service centers in all industrialized countries spreads the name of Tecnomagnete worldwide. Our mission is to introduce magnetism wherever there is steel, bringing added value to the customer. Our values Effectiveness Improving production processes, making operations more effective, economical and fully compatible with respect for the environment. Reliability Understood as the ability to create trust between us, with our products, and the customer who uses them. An investment that will last over time. Safety Designing responsibly in search of maximum performance, in compliance with the highest safety standards. We are constantly seeking the best that technology can offer in the industry. We work with leading manufacturers of machine tools, injection molding machines and handling systems; for over 10 years we have had a direct line to the Politecnico di Milano. Thanks to our know-how we are also able to develop dedicated solutions of high complexity. Moreover, MAG-AUTOBLOK TECNOMAGNETE SPA is certified ISO 9001: 2015.

- TUROMAK

TR

TR