| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

TEKNOPAR ENDÜSTRİYEL OTOMASYON SAN. VE TİC. A.Ş.

Teknopark Ankara İvedik OSB Mah. 2224. Cad. No: 1 F-48 06378 Yenimahalle / / ANKARA / TÜRKİYE

|

Contact Info: +90 312 395 9907

|

Hall: 12A

Stand: 12A-32

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Teknopar is an R&D performing SME, founded in 1996 and based in Ankara, and it is one of the leading providers of automation systems and solutions in Turkey for industrial facilities, energy, mobility sectors. Through the development of its engineering and production infrastructure, the company has extended its sphere of activity to provide customers with a wide range of services and end-to-end solutions where integrated applications of mechanical, hydraulic, automation, control and information technologies have been supplied. Developing technologies are closely monitored and the latest developments are included in our industrial applications, and industrial projects that are developed and implemented are planned to meet the requirements at the highest level both economically and technically. By combining information technologies with control, automation, robotics, and operational technologies, our company develops industrial communication systems, servo-controlled motion systems, embedded software, industrial software and data processing platforms. TEKNOPAR offers solutions compatible with its fields of activity in the following areas Information Systems M2M/IoT Big Data Artificial Intelligence Digital Twin Computer Vision Robotics Automation and Control Systems NDT and Test Systems

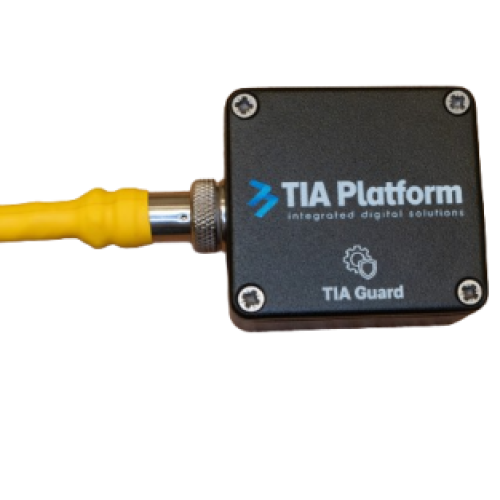

TIA Guard is an industrial equipment that prevents CNC machines from being damaged in the event of a bump/crash. 1.25 ms | Sensor detects collision <2 ms | TIA Guard recognizes collision, decides and sends stop command to the machine <100 ms | Machine stops TIA Guard detects and prevents collisions and impacts that may occur on machines during operation. It is especially designed to work in industrial environments. TIA Guard has a built-in vibration sensor with a high measurement range. Thanks to this sensor, which can read vibration values in real time, the vibration values at the point where the product is placed are continuously monitored and in cases exceeding the specified threshold value, it quickly intervenes and stops the machine or puts it on standby. TIA Guard has been developed to support IP68 standard and it is resistant to water, chemicals (e.g., machine oil) and dust particles. TIA Guard enables automatic adjustment of the acceleration threshold value according to the characteristics of the cutting tool and material, thus minimizing false stops and the risk of collision.

TIA Accelerometer is a flexible and high-performance three-axis accelerometer developed for use in industrial environments. TIA Accelerometer is the ideal solution for monitoring machine health and condition, detecting early wear of equipment such as cutting tools, bearings and improving production processes. It helps users to reduce costs, shorten maintenance durations and ensure continuity of production processes by identifying potential failures in advance. TIA Accelerometer is capable of operating on both DC and IEPE supplies and it is specifically designed for industrial environment conditions.

TIA Signal Conditioner is designed to remove the DC Bias voltage from the sensor outputs while supplying a constant current to IEPE type sensors. This ensures that the data is transmitted to a data acquisition system within the range from -10V to +10V. TIA Signal Conditioner improves signal quality by filtering out noise and unwanted frequency components while collecting data from IEPE type sensors. It has applications in dynamic sensors like accelerometers, microphones, and acoustic emission sensors that are compatible with the IEPE communication standard. It has a compact design. The constant current supplied by the four channels can be adjusted from 2 mA to 20 mA.

TIA Integrator is a remote input/output (I/O) device designed to control (e.g., on/off) machines, sensors and other industrial devices and monitor their parameters (e.g., on/off, pressure, temperature, flow rate) remotely. TIA Integrator is developed for monitoring and controlling digital signals from devices such as sensors or switches. It is used to monitor different signals and operating states of old machines (legacy/brownfield) and to monitor various buttons. TIA Integrator is used to trace various button states. For example, it can be used to turn on a motor, stop a machine or close a valve. It allows command of any industrial machine controlled by a button or a switch to be operated remotely. TIA Integrator is used to monitor analog data from sensors. For example, it can be used to monitor variables such as temperature, pressure or flow rate. TIA Integrator converts the analog data of sensors producing currents between 0-20 mA and 4-20 mA into digital values and stores them to a database.

TIA Microphone is an IEPE type microphone specifically designed for industrial environments. It offers great value, especially in critical operations such as predictive maintenance. TIA Microphone is an essential device for detecting sensitive conditions such as cutting tool wear, preventing machine breakdowns and ensuring the continuous flow of production processes. TIA Microphone enables real-time monitoring of equipment status and early detection of potential problems through audio analysis and by this way reduces the costs by machine downtime and maintenance operations. TIA Microphone is robust for the conditions of industrial environments and performs reliably even in these environments

No represented companies found.

- TIA PLATFORM

- TEKNOPAR

- TEKNOPAR ENDÜSTRİYEL OTOMASYON

- TIA ASSETHEALTH

- TIA PLATFORM INTEGRATED DİGİTAL SOLUTİONS

- TIA CNCHEALTH

- TEKNOBLAST

- TIA QUALİTYHEALTH

TR

TR