| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

SURTEK ENDÜSTRİ MAK.SAN.VE TİC.LTD.ŞTİ.

İOSB Mah. Marmara Küçük Sanayi Sitesi P Blok 25-26 İkitelli / Küçükçekmece / İSTANBUL / TÜRKİYE

|

Contact Info: +90 212 516 3384

|

Hall: 11

Stand: 1162

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Surtek End. Mak. San. Ve Tic. Ltd. Şti. was established in 2005 as the only representative of world s leading surface finishing company OTEC Prazisionsfinish GmbH in Turkey. Growing with its high quality products and service over Turkish, Middle Eastern, Caucasian, North African and some Far Eastern markets, SURTEK had become a leading solution center for surface finishing systems as the only representative of its partnerships in these markets. With its qualified and experienced staff, SURTEK is still developing its capabilities and keeping up with the changes in modern industry.In 2006, SURTEK had become the Turkish representative of Elma Hans Schmidbauer GmbH & Co. KG, which is really important company in ultrasonic cleaning/washing industry. With success achieved over time, SURTEK had started working with leading companies such as EVT Eiberger Verfahrenstechnik GmbH for closed loop solvent based degreasing systems, BLV Oberflachentechnik GmbH for water based cleaning systems and ICS for dry ice cleaning systems. These partnerships have vastly extended our product range in industrial cleaning solutions. All the companies that we are working as their representatives are world leaders in their own fields, which give us the advantage to deliver you the best solutions in surface finishing and cleaning problems, effective and economically.

The CF-T series is a high-performance benchtop version of the globally successful CF series with all the benefits of the CF concept. It is ideal for deburring and grinding industrial workpieces and especially suitable for finishing jewellery.

Disc Finishing Machines are modular in design and are available as standard with 1-4 process drums. The unique, patented gap system of the CF machines enables the gap to be set with an accuracy of 0.05 mm for dry finishing. The chassis is made of anodized aluminium profile and is therefore expecially resistant to corrosion and can easily be adapted to accept add-on equipment. All controls are accessible from the front and clearly laid out. Many years of experience has been channelled into these machines, making them very popular with customers.

The OTEC EF-Smart T is impressive with its compact design, low operating noise and intuitive operation. It delivers reproducible high-quality results. The Plug & Play principle allows fast and easy integration in your laboratory. Homogeneous, perfectly smooth surfaces are obtained with a significantly reduced workload. The EF-Smart T is the perfect precursor for automated processes. Thanks to the Industry 4.0 Ready package, which is integrated as standard, the processes can be monitored and controlled digitally.

Custom-designed workpiece holders make a significant contribution to the perfect processing results obtained by the DF-Series. They also ensure that the workpieces are mounted as quickly and efficiently as possible and considerably simplify batch processing. In recent years, OTEC has designed over 100 different types of holder. Furthermore, the process container features a water cooling system which keeps the polishing granulate at a constantly low temperature. This considerably extends the life of the process medium and ensures constant process quality, even at consistently high processing speeds.

Elmasonic Easy series ultrasonic cleaning machines are designed to be easy to use, all in stainless steel, in 12 different sizes. Operating at 37 kHz ultrasonic frequency, Easy series can be set to a temperature between 0-80°C and has an automatic shut-off feature at the end of a set time between 0-30 minutes. Devices larger than 6 liters have a drain valve for easy drainage. It offers fast and effective solutions especially in the dental and jewelry sectors. With its new Eco mode, it provides both quieter and more economical washing, while its Dynamic mode provides results even in the most difficult dirt by spreading homogeneous sound waves to every point of the tank.

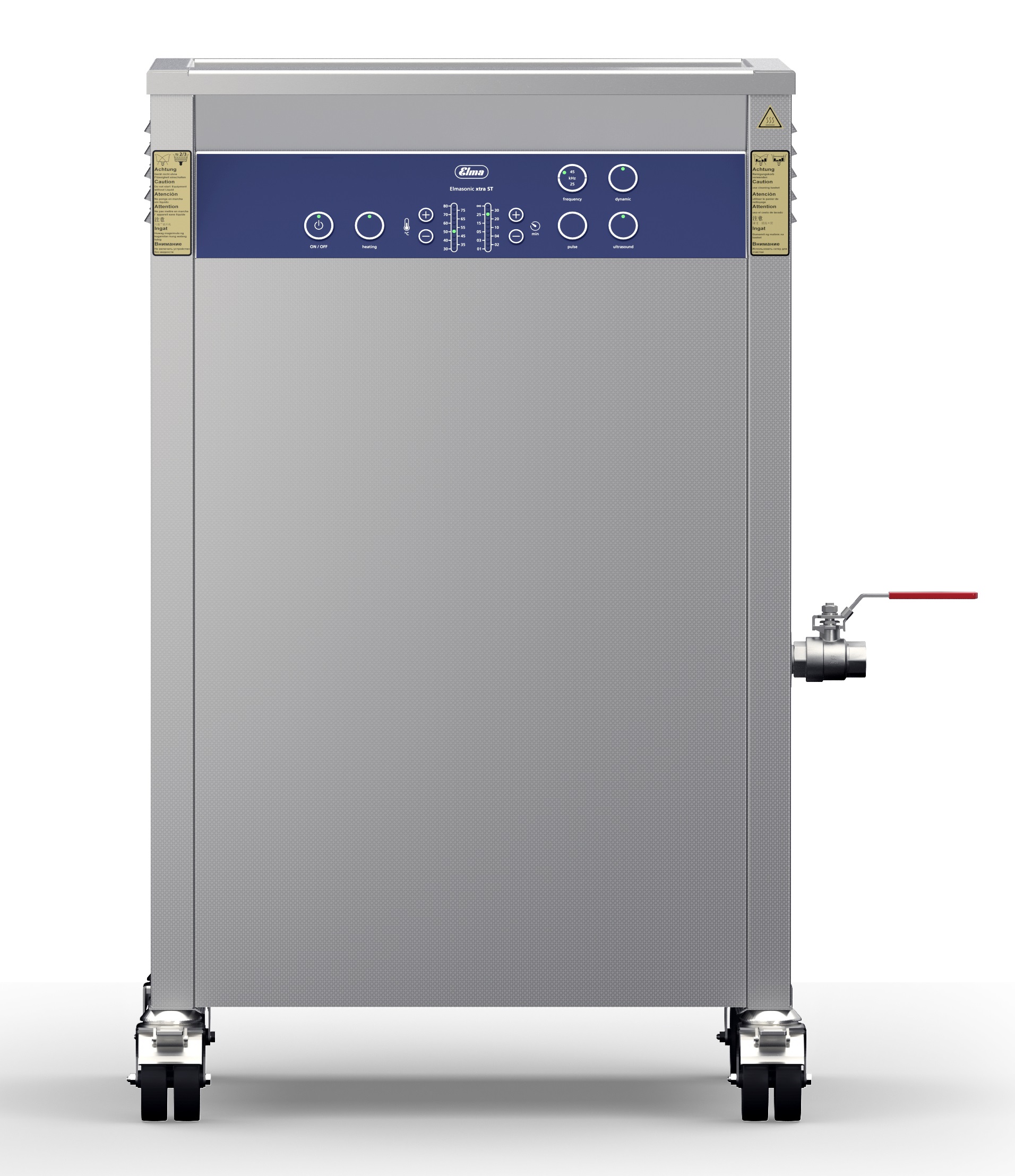

Elmasonic xtra ST is an ultrasonic device that can remove even the most severe contamination and is therefore ideal for extreme dirt loads in the field of industrial cleaning. With the two selectable ultrasonic frequencies, a diverse range of cleaning tasks can be successfully completed. For stubborn dirt, such as the removal of lapping and polishing pastes, 25 kHz is selected. At 45 kHz, sensitive surface materials can be gently cleaned and degreased. Different modes, such as Pulse, Sweep and Dynamic, offer more individual options to achieve a perfect cleaning result. The oscillating tanks are made of stainless steel with increased wall thickness and boast a high degree of robustness and durability.

The compact Elmasteam 8 basic with 8 bar steam pressure is the ideal steam cleaning machine for smooth and environmentally friendly pre- and final cleaning tasks. With the selectable pressure modes soft und strong , the individual regulation of moisture in the steam (wet or dry steam) and the strong heating power, the Elmasteam 8 basic is ready for even challenging cleaning tasks. The individually adjustable Eco-mode ensures that the unit closes automatically down to 3 bar operating pressure in order to save energy and cost. Cleaned parts can be easily dried with the optionally integrated compressed air function. For more user safety, Elmasteam 8 basic has an integrated, automatic Lock-mode. Water can be filled via the integrated funnel in the tank or with the optional water connection via the rear connection and the integrated pump. Regular decalcifications increase reliability in operation and the product-life of the heating. The decalcification programme can be easily started in Service-mode. Occuring sediments can be rinsed out following the operating instructions and using the rinsing set.

The DentalBlast 420 is crafted to offer superior handling and precise blasting for dental implants. With its dedicated tray system, dual nozzle setup, and a three-axis manipulator, this machine ensures meticulous surface preparation in a compact and efficient design. The manipulator is equipped with a rotation motor and pneumatic gripper for exact implant placement, enhancing the consistency and quality of the blasting process.

Designed for delicate and ultra-delicate cleaning processes, the xtra line 2 can be flexibly deployed and extended by adding baths when necessary thanks to its modular system concept. Even tanks of different sizes can be added to a single system. The compact, closed system design facilitates machine maintenance. Maintenance aids such as oil separators, filter systems, etc. are placed inside the system to save space. In addition, removable rear parts facilitate maintenance and repair of the machine. Even the entire pipe system can be easily intervened.

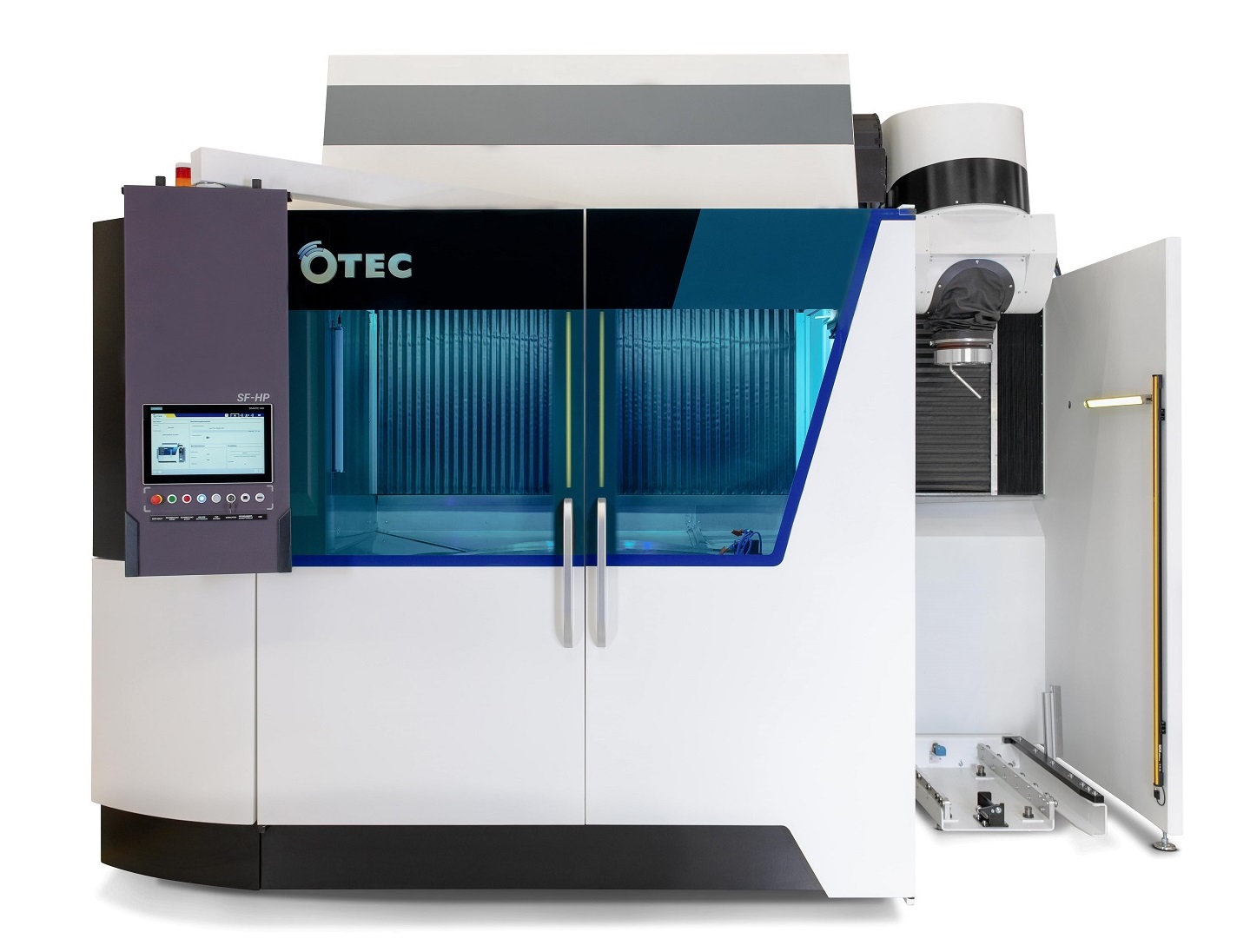

The SF -series offers deburring, rounding and smoothing in a single processing stage, in a very short time and without detriment to the contours of the workpiece. Path-controlled motion enables specific areas of a workpiece to be processed more intensely. Because of the tremendous processing forces involved, the SF units provide fast and economical finishing and guarantee absolutely reliable processing results.

The company has no registered brand information.

TR

TR