| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

SELSA OTOMOTİV SANAYİ A.Ş.

Minareliçavuş OSB Mah. N.308. Sok. No: 5/Z1 / Nilüfer / BURSA / TÜRKİYE

|

Contact Info: +90 224 219 2900

|

Hall: 6

Stand: 628

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Our Partner Company, SELSA, was established as a small workshop in 1992 in Bursa, Turkey. It started its business by manufacturing special machinery and has become a strong company in the precision machining sector by concentrating its business on mass production over the years. SELSA, which has not stopped making machines for itself throughout the years without ever losing its founding philosophy, established the SELSA MAKİNA company from within itself and set its goal as being a world-class manufacturer. It has become a very strong company in the domestic market by combining business ethics with its approach of minimizing human errors, increasing quality to the highest level, making sustainable production, being competitive in the market, and distinguishing itself from its competitors. SELSA is always ready to serve you as a business partner with its experienced staff in order to produce solutions that will facilitate the production of its customers.

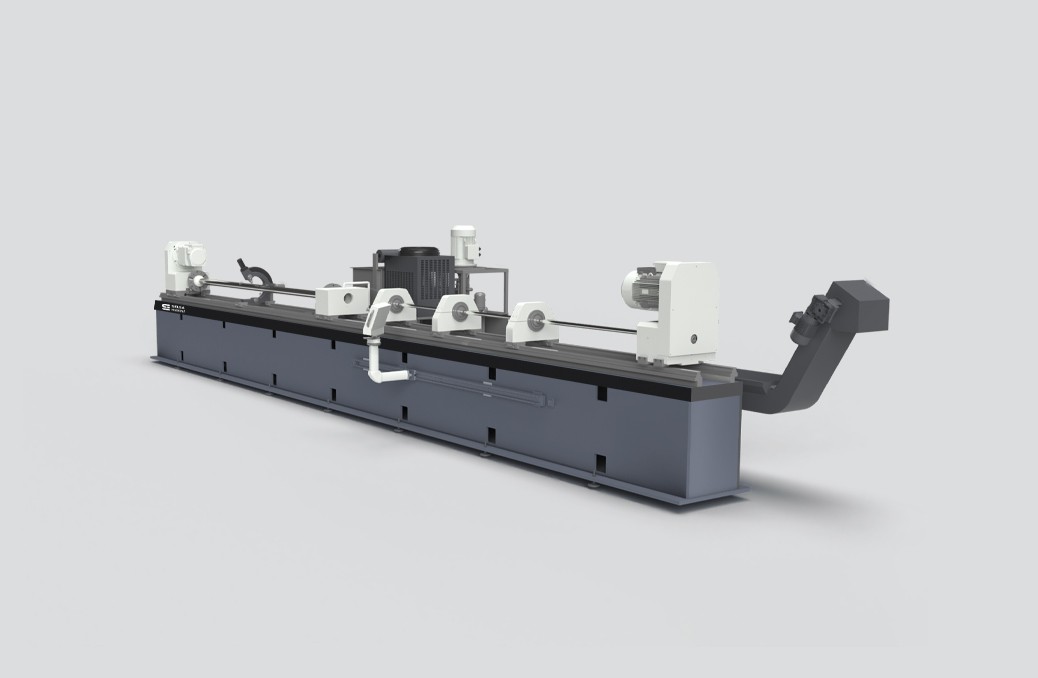

Max. 8 m length and max. Ø50 mm shafts; Legth Cutting, Finish Turning, Chanfering Turning of external diameters operations can be performed on a SP Series machine.

From Ø1.5 mm to Ø75 mm. It provides the opportunity to drill deep holes from 250 mm to 2000 mm. SL series deep hole drilling machines are designed to meet the high production and precision levels demanded. SELSA MAKİNA s extensive experience in machining and automation offers a reliable and high-performance system where every detail is considered. Since the machines are designed with reliability in mind, they are resistant to harsh production conditions. With the complete documentation and expert support offered, it provides customers with the confidence they need at every stage. These machines not only optimize production processes but also meet industry standards by providing custom solutions to suit customer needs. SELSA MAKİNA s engineering skills and customer-oriented approach make the SL series deep hole drilling machines a leading solution in the industry.

Designed to provide superior performance and excellent results after hole drilling process. Focusing on high precision and quality standards, the machine provides fast and efficient production with its high-speed operating capacity. Designed with a solid structure and long-lasting materials, our machine stands out with its durability. Also our Machine offers a perfect solution in reaming processes with its user-friendly interface, energy efficiency, and wide application area.

It provides rifling for barrels between Ø4mm and Ø13mm. With its compact structure, the machine takes up minimum space in your production line. Rotation speeds are powered by servo motors and can be programmed. It finalizes the barrel with high precision and controls, production data can be kept under control, and rifling-set quality can be kept constant for each product with automatic feedback. The machine provides convenience to barrel manufacturers in their production lines with its user-friendly and simple-to-use control panel. With its automation and robot installation infrastructure, it can be operated automatically in your production track if desired.

From Ø14.5 mm to Ø50mm, providing the opportunity to drill holes up to max. 2000 mm deep. BTA Series Deep Hole Drilling Machines are designed to perform large-diameter deep hole operations. The focus is on casting bodies, special bearings, vibration dampers, cooling infrastructure, and issues such as hole linearity, hole diameter, and surface roughness.

It can offer workpiece-specific production solutions in high-volume production. Spindle drives can be integrated into machines. Workpieces can be fed with the help of walkers or robots. Automatic tool compensation is possible with integrated measuring systems. Process and machine capabilities can be calculated and reported automatically. (Cmk, Cpk)

Clamping fixtures suitable for the workpieces are designed. The number of stations is determined according to the process and production time parameters of the workpiece. Necessary measurements can be checked during the process with the help of cameras and measurement probes. Loading and unloading stations can be designed manually or automatically. Operations such as drilling, reaming, threading, and milling are possible.

A laser micrometer suitable for the diameter tolerances of the workpieces is used. Measurement results of measured parts can be recorded and stored. Pareto analyzes can be made by creating reporting pages for measured parts. Cgk and GRR qualifications of the machines are checked.

Projects are developed to enable visual inspection of workpieces. Visual defects on workpieces can be detected with the Area and Linescan method. If desired, workpieces can be rotated 360° and error checks can be made on the entire surface. Workpieces can be loaded manually or with the help of a robot. Pareto analyzes can be performed according to error types.

No represented companies found.

- SELSA MAKİNA

TR

TR