| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

PERGEL MAKİNA SANAYİ VE TİCARET LTD. ŞTİ.

Yeni mahalle Giresun cad. No:4/A / Piraziz / GİRESUN / TÜRKİYE

|

Contact Info: +90 531 928 0387

|

Hall: 12A

Stand: 12A-22

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

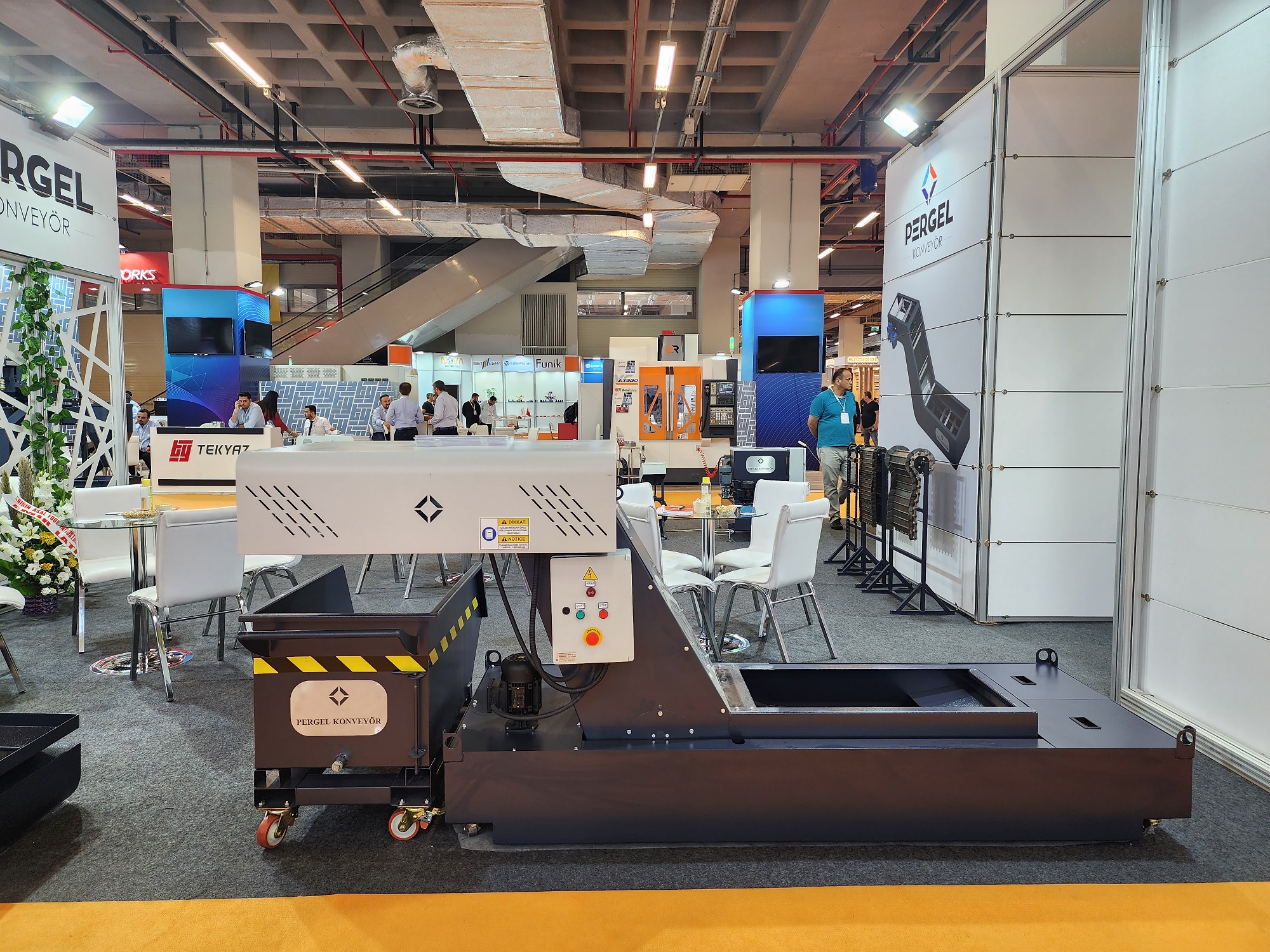

Pergel Konveyor designs and manufactures machines that offer solutions according to the demands of the machining industry, such as transporting, filtering and recycling waste sawdust and cutting oils formed after machining. In addition to products such as chip conveyors, separators, centrifugal systems and chip elevators, our company can make special designs and produce central solutions for companies. Combining engineering and craftsmanship with state-of-the-art machinery with more than 25 years of manufacturing experience, Pergel Konveyor carries out strict quality control, starting from the project design of the product until the tightening of the last bolt.

Hinged belt conveyors are used to convey a broad range of long, rough, curled and crumb type chips which come from from transmission steel, work tool steel, aluminum alloy metal, as well as other materials such as teflon, delrin, etc. Hinged belt conveyors are most commonly used type of chip conveyors.

Scraper conveyors are used to convey small chips and particles which come from grinding and honing various composite materials such as iron, cast-iron, brass-alloys, and sintered metals.

Magnetic conveyors are used to carry dust, crumbed iron chips, and other metal particles. There is no damage risk of pallet and particularly the product carried since the magnetic carriers has no contact product and chips. The production cost of these type of conveyors is the highest due to the neodymium magnet mounted on the pallets.

Drum filter unit ensures problem-free conveying dusty chips and crumb chips with its special designed drag conveyor system. Filtered drum filters coolant around 50 microns and makse it possible for reuse in the system. Coolant comes from amchining center is poured into dirty water reservoir of the drum filter and dusty and crumb chips are deposited to bottom in this reservoir and then transmitted to chips reservoir by scraping method. Thus, chips are seperated from liquid by scraping method.

This device is used to load chips which come out from machine tools to available containers or silos by chip carts. Chain chip loading and discharging elevators have a structure consisting of a steel construction hull. Elevators can be manufactured according to desired size.

Chip carts are braked and tilting wheeled carts which are used for collecting chips which come from chip conveyors. It can be easily moved under conveyors and emptied to chip storage with its special design.

Seperator is designed to be uses for, machining centers, machine tools and grinding machines where clean coolant is needed; honing centers; and pumping stations which allow particles at micron level.

Roller conveyors are machine groups that enable the loads to be transported in industrial transportation systems to be moved in the desired direction on rollers. They are systems capable of carrying linear and circular loads depending on their design. The loads to be transported are conveyed on rollers placed at certain intervals on the conveyor chassis.

Belt conveyors are the most commonly used transportation vehicles with their simple design and light body structure that increase production while easing the workload in mass production areas with their high carrying capacity that can be achieved in continuous material transportation and the ability to carry loads over long or short distances. The material transported may be wet or dry, and may be in pieces or pieces.

No represented companies found.

- PERGEL KONVEYÖR

TR

TR