| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

NANJING XINZHE CNC MACHINE TOOL CO., LTD

NO.9 FENGYUAN RD XIONGZHOU ST. LIUHE DIS. NANJING CITY JIANGSU PROVINCE / / / CHINA

|

Contact Info: +86 183 5182 3498

|

Hall: 12A

Stand: 12A-50A.1

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Nanjing Xinzhe CNC Machine Tool Co.,Ltd. was established in 2007. Located in Guabu CNC Industrial Park,Liuhe District, Nanjing, the company is mainly engaged in the research and development, manufacturing, technical consulting, sales and service of CNC machine tools, intelligent equipment and intelligent manufacturing systems. The company s main products include vertical machining centers, horizontal machining centers, gantry machining centers, five-axis machining centers, vertical lathes and various special machine tools, intelligent manufacturing production lines, and intelligent manufacturing workshop planning and construction, and many other kinds of CNC products.. In addition to the production base in Nanjing, the company has established branches in Chongqing and Guangdong.The company insists on being customer-centered and constantly innovating. From the standard vertical, horizontal, and gantry processing centers, it gradually develops a variety of high-efficiency and labor-saving automatic special machine tools and production lines to meet the processing needs of customers. Customers are spread all over the country and abroad to many countries.The company has independently developed special machines and automated production lines for full CNC parts machining, and has made major breakthroughs in leading companies of the industry such as Sinosteel, Sinotruk, and Fuhua Heavy Industries. The company adheres to the corporate tenet of attitude determines everything, quality makes the future , carries forward the spirit of innovation and excellence, builds a positive, dedicated and loving team, serves customers with heart and soul, and produces high-quality products!

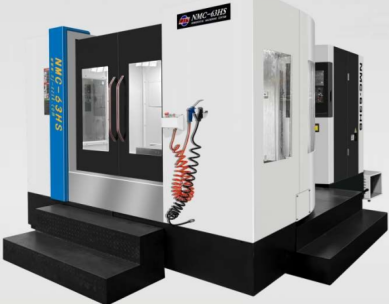

1. Adopt Taiwan HIWIN or PMI line rail, and the width of the Y and Z axis rails is up to 45mm; 2. The ultra-wide base is as stable as Mount Tai; 3. The double-layer arm structure of the force column increases the rigidity by 1.5 times; 4. The X-axis sliding seat has a super-large span, and the herringbone -shaped column design is as stable as Mount Tai; 5. The three-axis adopts Taiwan s external diameter 40mm C3 grade screw rod, and the three-axis adopts NSK original bearing (3062), which is pre-tensioned to prevent thermal displacement; 6. High rigidity BT spindle, ring spray design; 7. The machine tool parts belong to the famous brand of famous factory, and the top configuration in the industry;

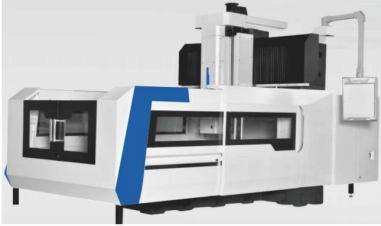

1. It adopts the internationally popular inverted T-shaped moving column overall bed structure, which has the advantages of high rigidity, good stability, and easy protection. 2.The main castings are made of high-grade high-quality cast iron, resin sand molding, and secondary aging treatment after rough machining to ensure the stability of precision. 3.Fully enclosed protection design, double-sided spiral chip removal structure, equipped with large-capacity cutting fluid tank and convenient machine cleaning air gun, optional chain plate type chip removal lifting device and chip storage car.

This machine tool is a CNC sorghum gantry machining center with good dynamic performance, accurate motion precision control, stable machining accuracy and good consistency, which can automatically complete the hole machining such as drilling, expanding, boring, reaming and tapping of parts under one clamping and the machining of milling surfaces, grooves, curved surfaces and other work processes. This machine tool has the advantages of advanced design concept, beautiful appearance, good overall rigidity, long precision retention, and a wide range of applications. It is widely used in large diesel machinery, agricultural machinery, chemical machinery, new energy, rail transportation, automobile, mining machinery, steam turbine, textile, aerospace, military, shipping, electric power, nuclear industry, metallurgy and other industries.

The machine tool adopts a crane structure, and the base is cast with a mineral casting formula from Switzerland. It has no internal stress and does not need to be aged to relieve stress, allowing the machine tool to maintain good static accuracy and stability. Mineral castings have good shock-absorbing properties, and the material itself can absorb the vibrations generated during processing, thereby ensuring good dynamic performance of the machine tool. The thermal conductivity of mineral castings, the main material of the machine tool, is one-fifth that of cast iron, which can ensure the long-term thermal stability of the machine tool.

Unique wall panel + moving column structure, plus X-direction three-rail design, providing powerful cutting capabilities, exceeding your expectations It has been verified by many customers that it is superior to the traditional fixed column structure in terms of rigidity, precision, speed and stability. All structural parts are subjected to finite element analysis, and strive to optimize the structure to ensure the stability of the accuracy of the machine tool in the cutting state, and the mechanical rigidity is increased by 30% compared with the traditional design.

XZ110 type horizontal boring and milling machine suitable for large workpieces with multiple sides machining, especially the complex machining of box parts, in the process of machining can be automatically exchanged for cutting tools, can be a clamping for multiple sides of the milling, drilling, reaming, boring, reaming, tapping, etc., combined with the expansion and contraction of the boring axis, to meet the processing of deep holes and other specific processes; the whole machine adopts the modern machine tool and control concepts, compact structural design, to ensure high efficiency and high accuracy of the single piece or a small batch of small and medium-sized products machining requirements.

No represented companies found.

- NANJING XINZHE CNC MACHINE TOOL CO., LTD

TR

TR