| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

MERTA PREFABRİK VE MAK SAN VE TİC LTD ŞTİ

Egemenlik Mah. 6106/35 Sok.No: 5 Bornova 35070 / / İZMİR / TÜRKİYE

|

Contact Info: +90 531 888 4108

|

Hall: 6

Stand: 620

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Merta Filtration specializes in optimizing the utilization of metalworking fluids, crucial components within the metalworking industry, through innovative filtration, management, and automation solutions. Our comprehensive range of services and solutions related to metalworking oils and emulsions, meticulously crafted by our design, production, automation, and engineering departments, is tailored to meet the demands of modern technology. Key offerings include central oil filtration and management projects, alongside bench-based filtration and automation systems, designed to enhance operational efficiency and productivity. In addition to our in-house production projects, Merta boasts the widest selection and inventory of paper filters in our country, essential consumables for filtration systems. Moreover, we proudly serve as the Turkish distributor for leading brands such as MIXTRON, providing water-driven proportional dosing pumps, EXOMIST, offering oil mist collector units, and SEIM, supplying screw-type high-pressure pumps. At Merta Filtration, we are committed to delivering cutting-edge solutions and unparalleled support to ensure the success of your metalworking operations.

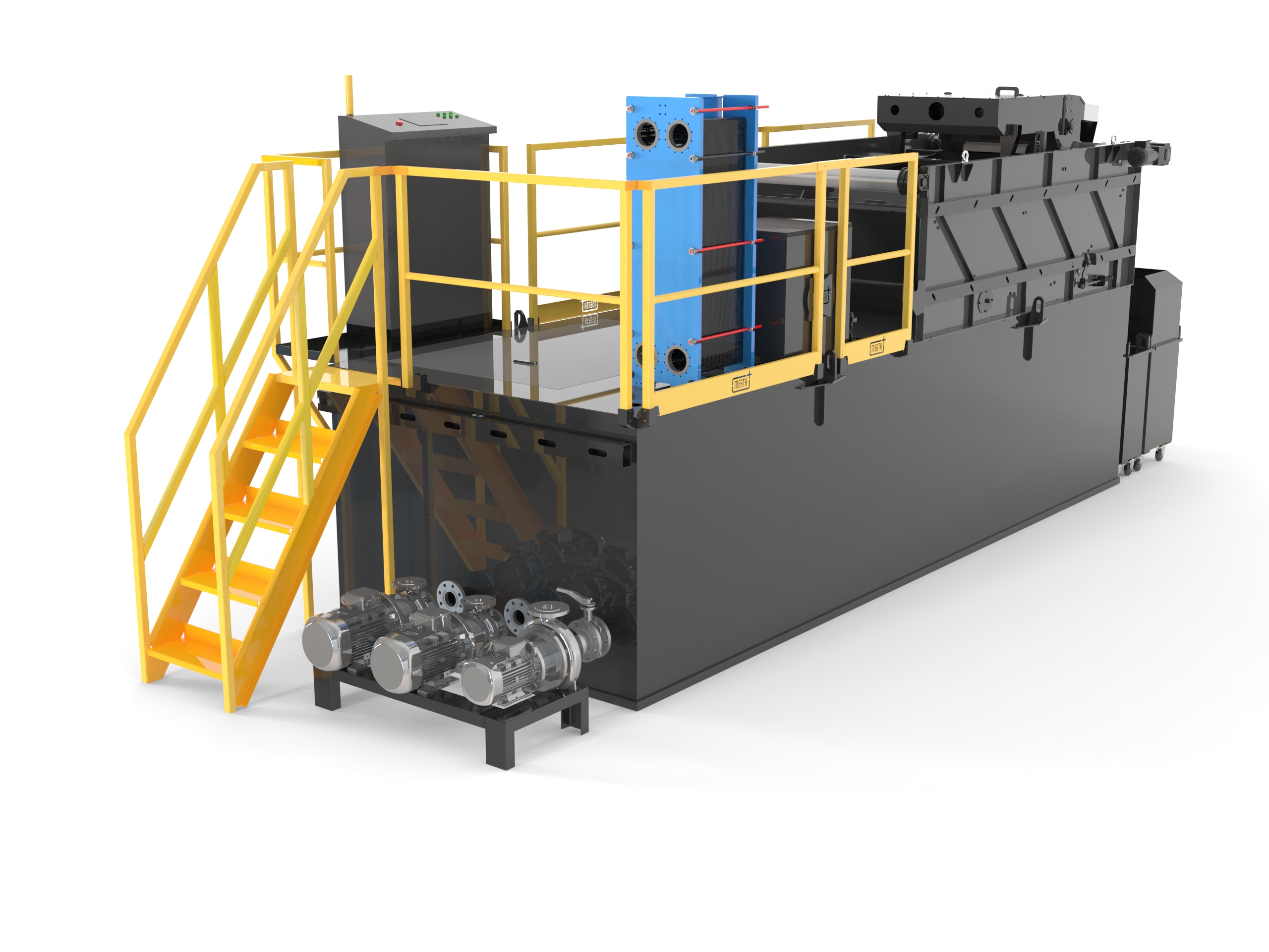

They are fully automatic systems that operate synchronously with the machines, in which more than one machine is connected to a central filtration system. Achieving Continuous Control and Standardization of Cooling Liquids: - Continuous monitoring ensures 24/7 control over contamination levels in cooling liquids, maintaining standardization. Efficient Filtration and Purification: - Effective filtration processes ensure dirty boron oil is filtered to desired levels, resulting in purified coolant free from pollution. Reduced Coolant Consumption: - Implementation of filtration systems leads to a significant reduction in coolant consumption. Enhanced Machining Operations: - Utilizing benches with standardized, clean oil results in decreased tool consumption and improved surface quality of machined parts. Streamlined Maintenance: - Eliminates the need for manual cleaning of coolant fluid tanks and reduces labor associated with maintenance tasks. Automated Coolant Management: - Automatic replenishment of coolant fluid eliminates the need for additional labor, enhancing operational efficiency. Holiday Mode Operation: - Central systems can operate in holiday mode during in-house shutdowns, preventing fluid deterioration. Prolonged Coolant Lifespan: - Efficient filtration and management systems contribute to extending the lifespan of coolant fluids, optimizing their usage.

The new generation high-efficiency industrial particle liquid filtration system is a filtration system that provides very high precision results, especially for the filtration of various industrial liquids, primarily metal processing fluids. It is used for filtering and separating all metal and non-metal contamination mixed into metal processing oils (boron oil and pure metal processing oils) used in the metal processing industry. The system performs filtration using a paper filter. The filtration level is determined according to the selected paper filter type, and filtration between 10 microns and 100 microns is possible. Thanks to its special sealing system, the Merta Compact filter ensures that the filtered liquid is trapped within the filtration area and raises the liquid level much higher than other filter types, allowing the filtered liquid to pass through the filter paper efficiently under its own weight. Paper Filtered Merta Compact filtration units operate fully automatically, and our company produces 3 different types of Compact units ranging from 150 liters/minute to 1,000 liters/minute capacity.

Our high-capacity filtration unit series, designed specifically for central systems, offers models ranging from 500 to 2,000 liters per minute. The Merta HDR series, equipped with paper filters and a special sealing system, efficiently handles high volumes of dirty liquid. By maximizing hydrostatic pressure, it allows for the selection of higher weight paper filters, enhancing filtration efficiency. Merta HDR outperforms other filtration systems, particularly in high-flow filtration needs, with its compact footprint compared to systems like Gravity belt filters.

Paper filters are the most effective solution for liquid filtration, especially in the metal processing sector (such as boron oil, grinding fluid, pure processing oils, etc.). Paper filters, commonly used in grinding machines, are frequently employed in serial operations, producing significant amounts of sludge, and are widely utilized in the metal processing industry. These filters come in various types, including gravity-type belt filters, compact units, hydrostatic units, and deep-bed units. Industries where paper filters are heavily utilized include pipe and profile factories, copper and aluminum cable manufacturing facilities, and the automotive industry, both primary and ancillary. With years of experience, Merta Filtration manufactures paper filters and filtration units that use them, ensuring the most suitable choices for your needs.

No represented companies found.

The company has no registered brand information.

TR

TR