| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

İDEAL MAKİNA END. ÜRÜN. SAN. VE TİC. A.Ş.

Esenkent Mah. Nato Yolu Cad. No: 277 / Ümraniye / İSTANBUL / TÜRKİYE

|

Contact Info: +90 216 540 8855

|

Hall: 11A

Stand: 11A-49

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Ideal Makina, founded in the year 2004, is continuously performing with its dynamic company structure on various industrial and medical applications with its right product, high quality service principle. Ideal Makina is supplying solutions to special requirements of customers with its developing engineering solutions in an innovative way. The company is providing a worldwide distinguished source of suppliers together with engineering genesis to its valuable customers. The process starting at the pre-sale stage, is being carried to the aftersales stage together with on-site applications of the Technical Service Team and providing of spare parts, service & maintenance and on-site applications. Ideal Makina is providing special key solutions to special demands of customers with its 1000 m2 indoor area in Istanbul. Chemical Dosing Pump Stations, Polymer Preperation Units, Nitrogen & Oxygen Generator and Cylinders Filling Stations or Containers, Pneumatic Conveying Systems, Air and Gas Compressor Systems, Skid Mounted Pug & Play user friendly equipments etc. are specially produced solutions according to customer specifications. All parts are being prepared for shipment after some specific tests like pressure, flow, temperature, noise, leakage etc. It is being allowed against to demand for customers or third party auditors to witness these tests and make their own controls on each equipment. End users of each imported equipment are being trained with technical and operational information in order to use the machines trouble-free on site.

IDEAL MAKINA PSA Nitrogen Generator Systems produce gaseous nitrogen from compressed air on site and offer a cost-effective, continuous and safe alternative to traditional nitrogen gas sources such as cylinders or cryogenic liquid.

As a compact aluminium series (AHD) for volume flows up to 110 m3/h and with welded vessels for volume flows up to 3050 m3/h as part of the standard series. Higher volume flows are available upon request. Common to both series is consistently high quality compressed air.

WITH CATOX (DEOXO) TECHNOLOGY, YOU CAN PRODUCE NITROGEN GAS UP TO 99.9999% PURITY! Forget your cylinder or liquid nitrogen purchasing costs and produce your own nitrogen with IDEAL MAKİNA CATOX NITROGEN GENERATORS! IDEAL MAKINA is the one and only supplier of producing Nitrogen with 99.9999% purity in Turkey. When it comes to the use of very high purity (1 ppm O2) nitrogen gas, you can produce ultra pure nitrogen gas in your own place with our CATOX Ultra Pure Nitrogen Generators, which is the only innovative and cost-effective solution instead of traditional liquid nitrogen supply.

It is very easy to produce your own nitrogen gas and fill your empty nitrogen cylinders with Ideal Makina Nitrogen Generators and mobile container cylinder filling stations! Consisting of high efficiency equipment selected to work together in harmony, the only need for Container Nitrogen Generator System is the power connection. It is very easy to produce your own nitrogen gas and fill your empty nitrogen cylinders with Ideal Makina Nitrogen Generators and mobile container cylinder filling stations! By producing your own nitrogen gas which is much more economical compared to the cost of your cylinder purchasings, you can fill your cylinders by yourself and can save considerably. Pipe connections, electrical wiring, main energy distribution together with control panel and all accessories in the container are assembled in the most accurate way and ready to be used. The produced high purity nitrogen gas is being filled into nitrogen cylinder bundles at 300barg pressure and fully responds to your variable nitrogen consumption. These systems are presenting the produced nitrogen gas uninterruptedly in the desired quantity, required pressure and high purity. Deep experience of having installed more than 500 nitrogen & oxygen generator systems for more than 16 years; İDEAL MAKİNA guarantees high quality of Plug & Play Nitrogen Generator Systems. With the container type nitrogen cylinder filling station designed by İdeal Makina with a special design, you can produce nitrogen gas much more economically compared to your cylinder purchasing costs and can make serious savings! Please contact us for our container designs that are resistant to all atmospheric conditions and corrosion. They can provide the maximum working performance required for all sound and heat insulated system units. ADVANTAGES Mobile, heavy duty, sound and heat insulated, ISO locked containers Ready system with all electrical and mechanical assembles completed. Uninterrupted operation in summer and winter equipped with air conditioners and heaters Gas production and cylinders filling in any climate conditions on the field Factory-tested ZERO LEAKAGE . Ease installation and commissioning on site. Easy transportation to another place when requested Little space usage with its compact structure. Main Power Distribution Panel User friendly, automatic START STOP . Environment Friendly Design Ability to work with field type diesel electric generators

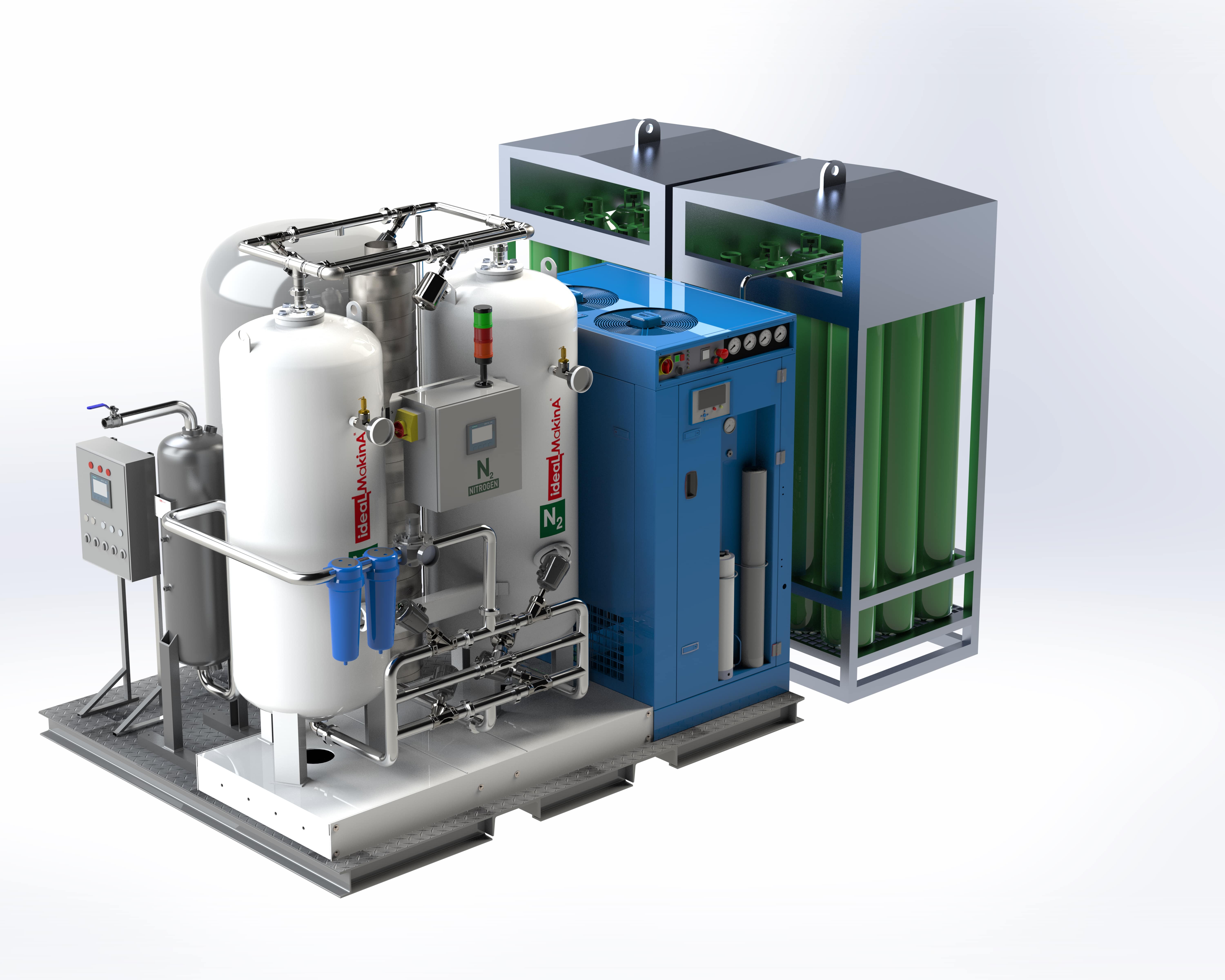

Skid Mounted, All In One, Ready To Be Used! Consisting of high efficiency equipment selected to work together in harmony, the only need for Plug & Play Nitrogen Generator System is the power connection. It is very easy to produce your own Nitrogen gas and fill your empty Nitrogen cylinders with Ideal Makina Nitrogen Generators and mobile skid mounted cylinder filling stations! By producing your own Nitrogen gas which is much more economical compared to the cost of your cylinder purchasing, you can fill your cylinders by yourself and can save considerably. Pipe connections, electrical wiring, main energy distribution together with control panel and all accessories in the skid mounted are assembled in the most accurate way and ready to be used. The produced high purity nitrogen gas is being filled into Nitrogen cylinder bundles at 300barg pressure and fully responds to your variable Nitrogen consumption. These systems are presenting the produced Nitrogen gas uninterruptedly in the desired quantity, required pressure and high purity. Deep experience of having installed more than 1000 pcs Nitrogen generator systems for more than 16 years; IDEAL MAKINA guarantees high quality of Plug & Play Nitrogen Generator Systems. With the skid mounted Nitrogen cylinder filling station designed by İdeal Makina with a special design, you can produce Nitrogen gas much more economically compared to your cylinder purchasing costs and can make serious savings! ADVANTAGES Little space requirement with its compact design. Can be carried by forklift, pallet truck or Crane and is mobile. Produced with optimum design considering the ease of maintenance in placing the equipment on the skid. Nitrogen production capacity, pressure and purity settings made by IDEAL MAKINA engineers beforehand. With all electrical and mechanical assemblies installed, they are placed in the field and put into operation in a very short time. The availability of necessary thermal switches are in the Main Electricity Distribution Board. The only need will be an electrical cable that must be provided by the end ser. No concrete base needed. Final product that has been tested, ready to use and finalized in IDEAL MAKINA factory in Istanbul. Electricity distribution panel, high pressure safety accessories and pipe connections leakage tests completed. Provides uninterrupted supply in variable Nitrogen consumption through storing at 300 barg Nitrogen bundles. User friendly, automatic START STOP . Remote control by a GSM Module is an option.

Gas mixing is another alternative to pure nitrogen or oxygen cutting, where a specific blend of those two gases is used. This process behaves very much like a nitrogen cutting process; however, the addition of a small amount of oxygen increases the available energy in the cut. This mixture allows for the cutting speed to increase compared to cutting with nitrogen at the same laser power (as much as 30 percent faster linear feed rate) and at the same time, it reduces burr formation, resulting in a better-quality cut edge in thicker mild (carbon) steels. Additionally, the extra energy of this gas mixture compared to pure fusion cutting with nitrogen allows the range of possible thicknesses we can process with our available laser power to increase. Materials that would once have needed oxygen can now be processed with mixed gas at a higher speed and with excellent quality. The idealMixer120 is compact, portable, mixes in real-time, and supports cutting pressures up to 30barg.

No represented companies found.

The company has no registered brand information.

TR

TR