| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

GEBR. HELLER MASCHINENFABRIK GMBH

Gebrüder-Heller-Straße 1572622 Nürtingen / / / GERMANY

|

Contact Info: +90 538 220 9511

|

Hall: 6

Stand: 625

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

HELLER was founded in Nürtingen/Germany in 1894 as a small craft business. Today, the global group of companies, employing more than 2,600 people (status 31 December 2023), develops and produces state-of-the-art CNC machine tools and manufacturing systems for metal-cutting applications. Five production facilities in Europe, Asia and North and South America ensure a reliable supply to customers from many different sectors. In addition, HELLER is represented in all major markets with its own sales and service subsidiaries as well as qualified service partners. The HELLER product range comprises 4-axis and 5-axis machining centers, mill/turn machining centers, special-purpose and process machines, machines for crankshaft and camshaft machining as well as coating modules. The portfolio is supplemented by a modular range of services and an expanded spectrum of solutions for the digitalisation and automation of production.

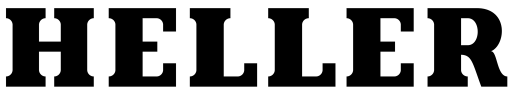

The perfect 4-axis machining center must be capable of being configured to your requirements, produce reliably even under extreme loads and offer a fair price/performance ratio. Our solution: HELLER H-series 4-axis machining centers. Components that have been reliably used in mass production for years coupled with a high dynamic guarantee you robust processes even at their limits, seven days a week in 3-shift operations.

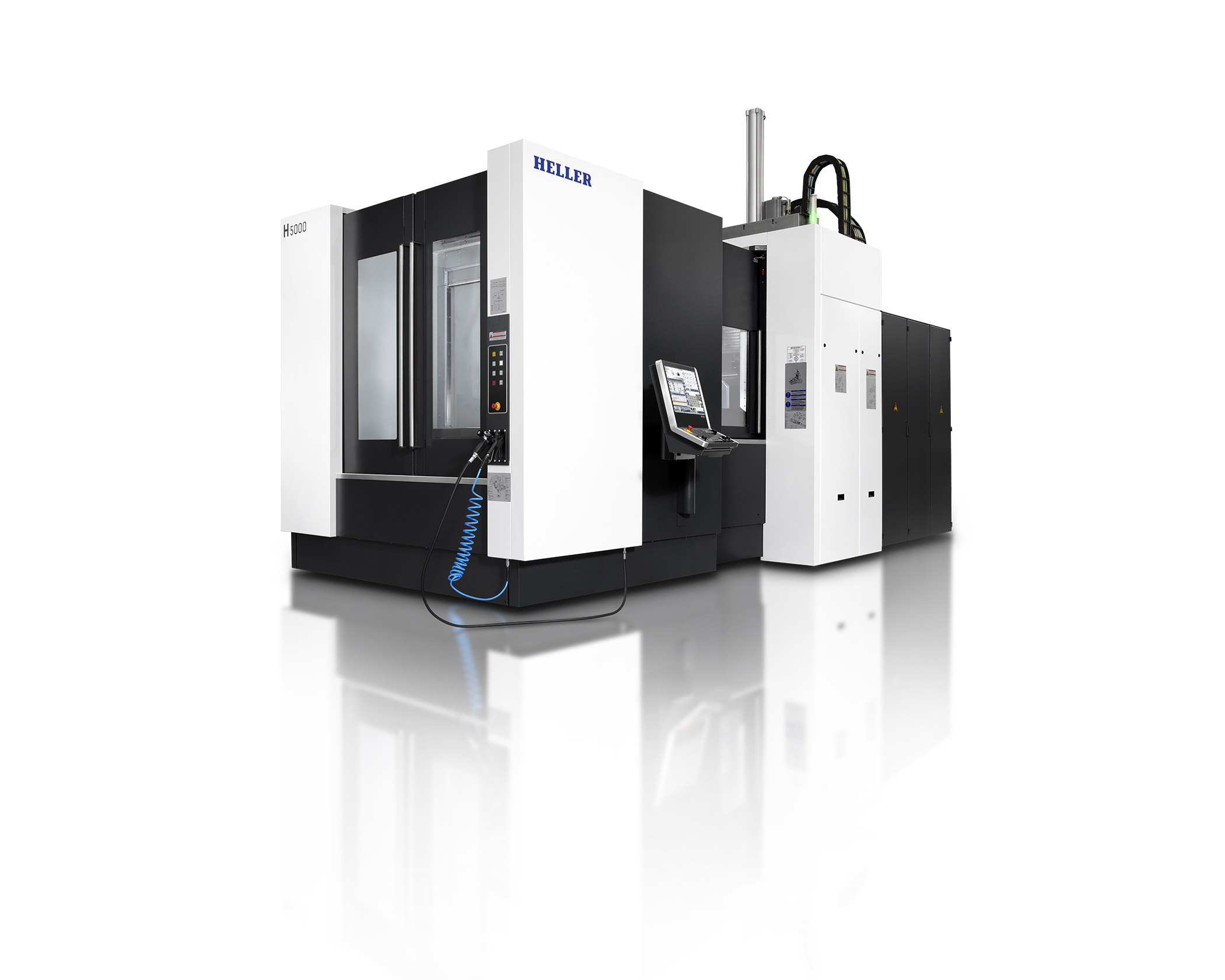

The 5-axis machining centers from the HF series are optimally equipped to meet the exacting requirements of modern production processes. Enabling 5-sided and simultaneous 5-axis machining, they allow you to handle many different tasks on a single machine. Highly productive and flexible, with easy operation and maintenance, available with pallet changer or table loading.

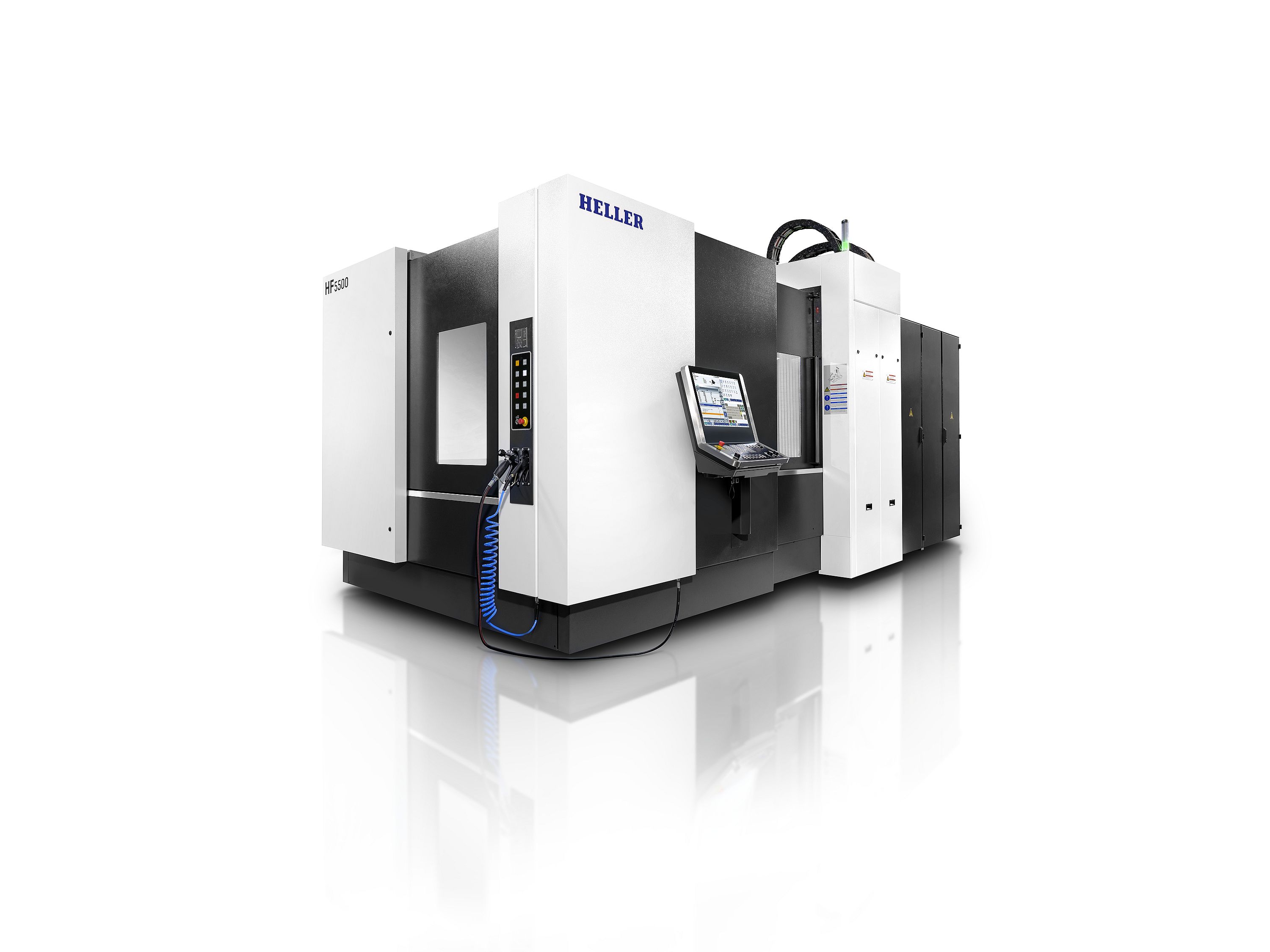

With its head kinematics, the new generation of the 5-axis F series has been designed from the ground up for flexible series production. Like all HELLER machines, they set a benchmark for cutting performance and precision. Other highlights include free chip fall, short idle times, optimum automation capability and compatibility with the H and FP series for a wide range of workpieces. In addition, the new models come with top-of-the-range specifications and the option to add technologies such as Mill-Turn, interpolation turning or power skiving.

No represented companies found.

- HELLER

TR

TR