| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

FMB MASCHINENBAUGESELLSCHAFT GMBH UND CO.KG

Paul-Hohe-Str. 1 / Bayern / / GERMANY

|

Contact Info: +49 9392 801281

|

Hall: 9

Stand: 907

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Welcome to FMB, the pioneer for automatization With a dedicated team of 200 skilled workers, we develop and produce state-of-the-art bar feeders and handling systems in the heart of Bavaria, in Faulbach. Our products are the heart of the automatization in industrial manufacturing and help to increase the efficiency and precision of our customers worldwide. Manufactured locally, appreciated globally Our local manufacturing is not just a mark for German quality but it also allows us to cater to the individual needs of our customers in a fast and flexible way. Our excellent service is a promise that we keep at every step. As market leader we not only set trends but redefine them. Innovation is our passion it drives us to continually set new standards in technology and quality. Every product is proof of our constant search for perfection. Partnership is our principle We strongly believe that the key to success lies in the strength of our partnerships. A transparent and open communication with our customers and employees forms the base for exceptional performances. At FMB, every customer and every employee is part of a big family in which team spirit and job satisfaction lead to outstanding results.

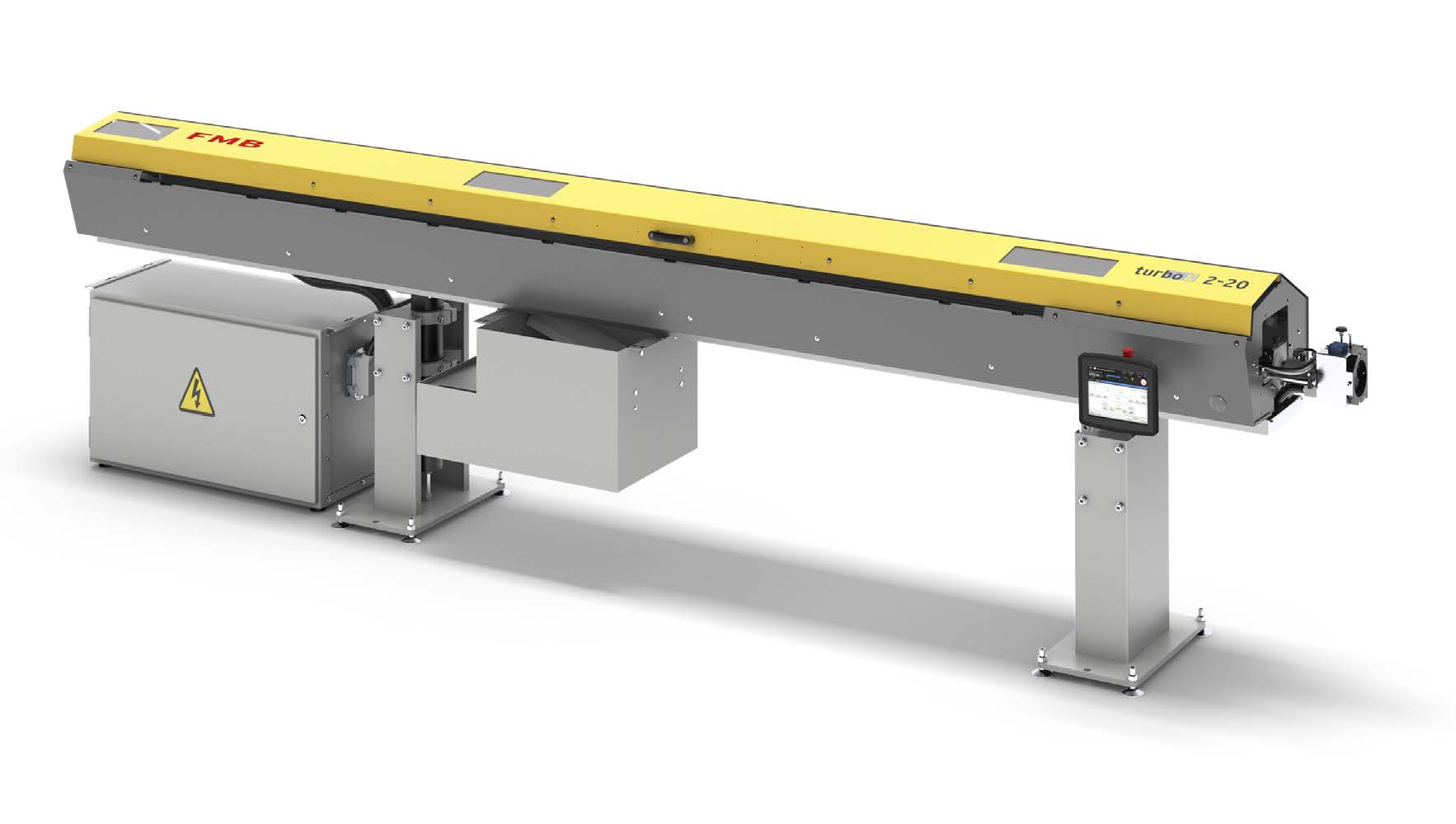

The turbo RS 2-20 guides material bars seemlessly right up to the lathe s spindle with a movable guide module. The bar feeder operates on the two-step feed principle, known from the turbo-series. By pivoting the pusher, this allows for a very compact and thus space-saving design. Its working area are sliding headstock lathes with a nominal diameter up to 23 mm which are intended for the use of small and average diameter ranges.

The turbo RS 3-38 guides material bars seemlessly right up to the lathe s spindle with a movable guide module. The bar feeder operates on the two-step feed principle, known from the turbo-series. By pivoting the pusher, this allows for a very compact and thus space-saving design. Its working area are sliding headstock lathes with a nominal diameter up to 38 mm which are intended for the use of small and average diameter ranges.

No represented companies found.

The company has no registered brand information.

TR

TR