| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

ERKAN CNC TEKNOLOJİLERİ SAN. TİC. LTD. ŞTİ.

İMES Sanayi Sitesi C Blok 301 Sokak No: 2 / Ümraniye / İSTANBUL / TÜRKİYE

|

Contact Info: +90 216 420 3639

|

Hall: 7

Stand: 713

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

CNC PRODUCTION SOLUTIONS EXPERT We are the Türkiye distributor of the world s leading machine tool manufacturers. We bring together the globally well-known brands Apec, Gentiger, Emco, Microcut, LEOMILL and Yanyang machines with Türk manufacturers. We are a complete production solutions provider in EDM wire cut erosion, die-sinking erosion, 5-axis and 3-axis machining centers, laser texturing, turning centers, additive manufacturing and automation, which are among the main manufacturing technologies. We offer turnkey production solutions from single machine to full automation smart factory solutions to various industry segments, automotive, aerospace-defense, white goods, energy, medical, packaging and mold making. Our company, established in 2002 to serve the Türkiye industry with high-tech products. Continues its activities in Istanbul in the head office, showroom, application center, logistics warehouse and free zone units; we have representative offices in Ankara, Izmir and Bursa. We are the market leader in EDM consumables and after-sales services, other than machinery and system sales. We serve Turkey s leading manufacturers with our knowledge, experienced, expert sales and after-sales teams. We would like to work with you too. Our aim is to offer efficient, sustainable and more profitable production solutions customized to your needs and goals, rather than selling excellent machines with competent technical support behind them. How about a coffee to meet?

A special CNC machine for the aerospace industry This CNC machine, specifically designed for the aerospace industry with its capability to process superalloys, features a robust T-shaped body and high-speed X, Y, Z axes driven by a ball screw. The optionally available Multiple Pallet Pool (MPP) system uses a zero-point fixture, allowing for much more precise exchange movements. This system saves time by enabling pre-execution of loading and unloading operations, thereby increasing the machine s effective utilization rate. The Multiple Pallet Pool, available in 6, 12, and 18 options, is an ideal solution to enhance efficiency and production capacity.

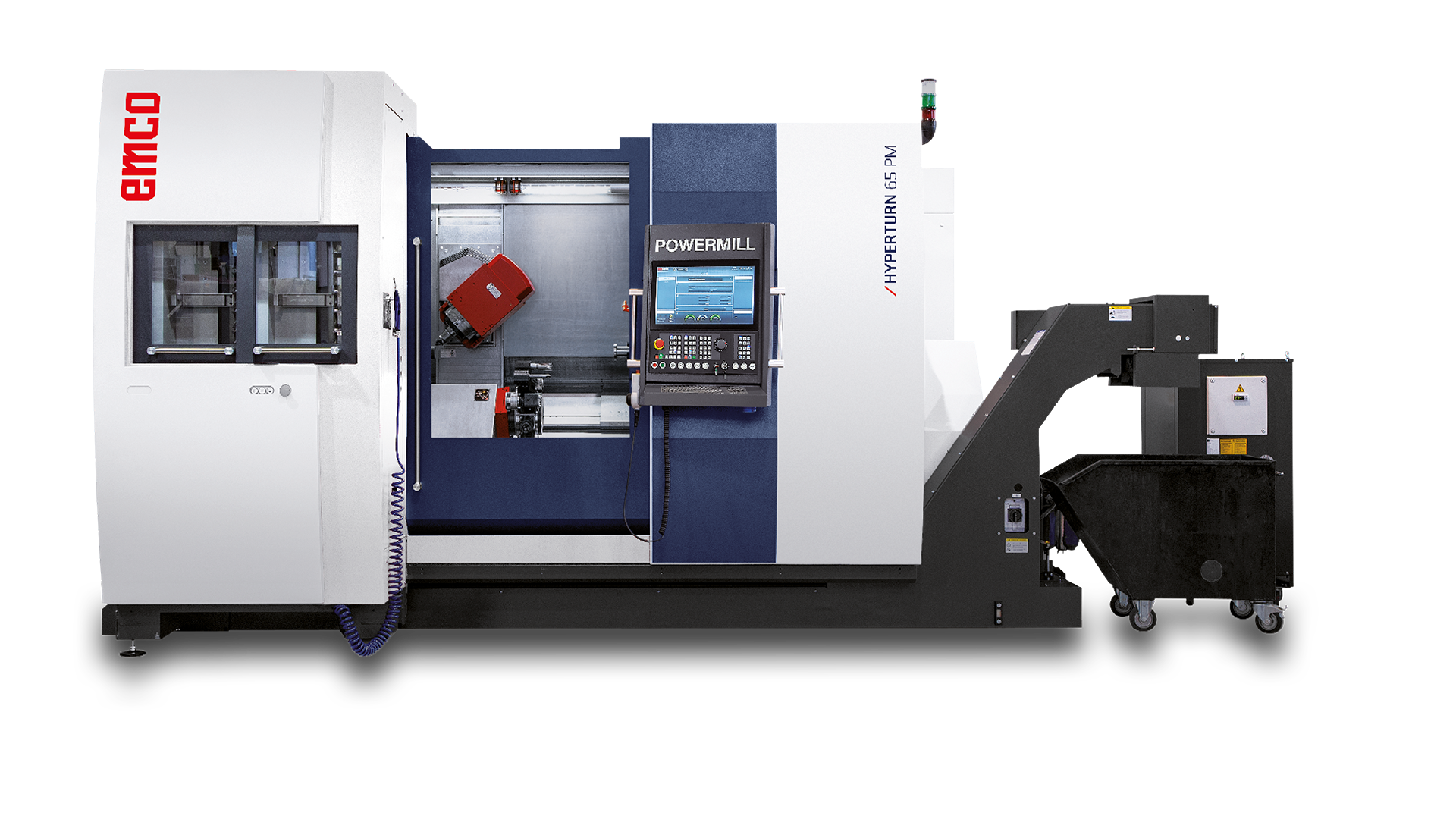

Emco HT65 PM Solve complex tasks with ease The Emco Hyperturn Powermill family combines maximum flexibility, power, and precision. As a turning and milling center for small and medium-sized production series, it meets all the requirements for the production of highly complex, high-precision workpieces. Impressive performance and flexibility: The Hyperturn Powermill series offers versatile machines for the multi-axis machining of complex components.

Exceptional Features This CNC machine, with reinforced casting and enhanced supports, stands out with its 45° table design that is easy to disassemble and clean. The tool measuring unit is placed inside along with the table to prevent tool changes and avoid chip contamination. The disk-type magazine tool increases efficiency, while the wide side door and automation interface allow it to be equipped with automation equipment, offering easier cleaning and maintenance. The interface is located in the center of the table that can be installed with automation equipment, saving space with its compact footprint.

With special design of machine structure GENTIGER GT-1160MS machining center provides unmatched stability comparing to conventional machines. The robust column and base design allows the machine to fully represent its exceptional stability in heavy cutting and high speed machining. Three axes are all mounted with high rigidity linear guideways. Rapid feed rate can reach 30 mimin (GT-1160MS) and 45m/min (GT-1160MS Plus). The machine design conforms to the ergonomic principle, which makes the machine operation and parts loading/unloading mare convenient and smoother.

GENTIGER 3-axis machining center, high rigidity machine structure, with high-speed spindle, high-level controller, high-power motor, precision scarping, show the machine of good rigidity, high speed, high precision and high efficiency. The X-axis travel is from 450mm to 3000mm, provided to meet customers. It is suitable for mold, aerospace, automobile manufacturing, medical materials, precision parts processing and other industries.

It is the machine that takes up the least space in the sector. It has the latest version 3D design program. X, Y, Z axes driven by high-speed screw shafts, A and C axes driven by torque motors. With this design, the moving part and the counterweight centers are kept concentric, effectively reducing vibrations caused by high speeds. The entire machine is equipped with Heidenhain optical scales. Each axis is equipped with scales to effectively ensure precision and stability. There is a device that prevents dust, oil, water and gas pollution to extend the life of the optical scale. Gantry type body design The drive center of all three axes is located at the center of gravity, thus greatly increasing the dynamic stability of the body.

High productivity in mold making, simple or precision part manufacturing and general engineering projects. Economical choice for fast return on your machine investment. Wide Base A Columns Column bases are greatly expanded to increase the dynamic and static strength of the machine. The A shaped column achieves excellent damping coefficient values to cope with heavy cutting loads. Thus, machining quality is increased and the life of the cutting tool is extended. High Performance Spindle This advanced spindle design is used with high strength ceramic ball bearings and maximum axial thrust is provided with minimum thermal effect. Spindle front and rear holes are on the same axis. Mitsubishi M80 Control Unit MC series machining centers use user-friendly Mitsubishi M80 control units with easy cutting modules.

- LEOMILL

TR

TR