| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

ERİŞ MAKİNA SANAYİ VE TİCARET A.Ş.

10016 Sokak No: 78 AOSB / Çiğli / İZMİR / TÜRKİYE

|

Contact Info: +90 232 324 3024

Web: https://erisrs.com

|

Hall: 11A

Stand: 11A-20

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

It is an engineering company that develops robotic automation systems for all industrial sectors and has taken its place among the leading institutions in this field. Supporting your current and future company strategy with the innovative and flexible solutions it offers is among its primary objectives. Engineering solutions that customers need; It offers you on a turnkey basis with its expert staff. The difference in the field of robot applications is that it can solve the entire project within the company with its own personnel. Thanks to this feature, it offers quality, minimum cost and effective solutions in line with the needs and expectations of the customer. It makes a difference in the sector with consultancy in the purchase of CNC machine tools, turnkey projects and after-sales technical support services in machine automation. Target sectors; are various industrial branches that produce with machining. Automotive sub-industry, textile machinery manufacturers, agricultural machinery manufacturers, fasteners industry, medical, aviation, defense industry, mold industry, accessory manufacturers are just a few of them.

MC2500 is one of the systems installed on the newly developed M platform. M stands for Modularity. This platform contains several systems on a single body. In this way, 85% of different kinds of systems are ensured to be the same. This creates advantages such as maintaining user habits, taking up less space, and reducing purchasing costs due to production. The MC2500 is an intelligent machine feed solution with a camera. Mechanical adjustment has been eliminated in order to simplify working on different parts. The system can feed any workpiece that can balance itself to any type of machine.

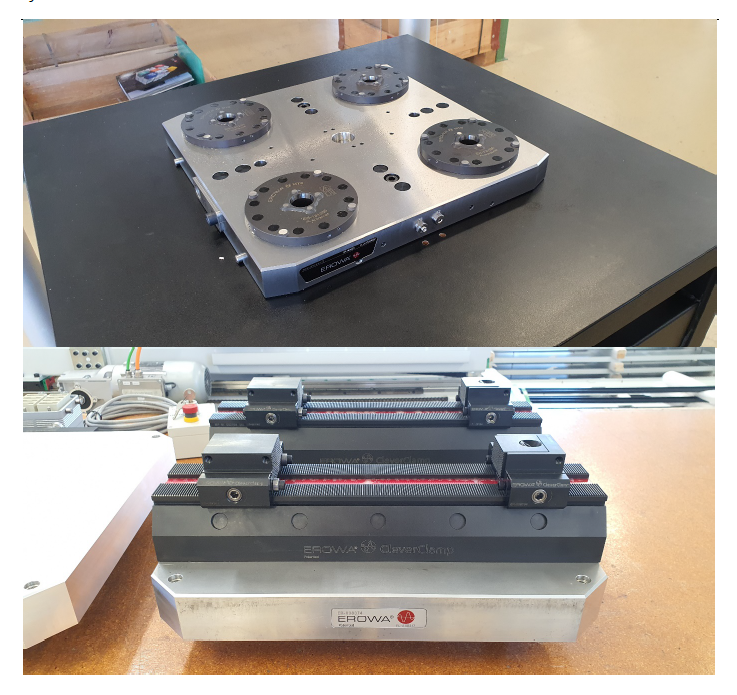

High performance on little floor space The EROWA Robot Easy 250 provides many useful and innovative functions on little floor space at an attractive purchasing price. The Robot Easy can also easily be integrated with existing machines to boost their productivity. Its solid design ensures flawless pallet exchanges. Workpieces with a maximum weight of 250kg can be safely and reliably loaded onto the machine tool. Depending on the pallet size, the magazine can be configured for 4 to 60 magazine positions to suit your own requirements. Large workpieces measuring L 500mm x B 500mm x H 400mm can also be accommodated by the magazine. Thanks to its compact monobloc design, the Robot Easy can be positioned beside the machine and made operational in a short period of time. The Robot Easy is suitable for lateral or frontal machine tool loading. Depending on the workpiece size, there is a choice of two different transfer axes. The transfer axis for EROWA s system sizes PC210, UPC and MTS has a range of 2100mm from the Robot s outer edge. The light axis for EROWA s system sizes ITS 50/72, ITS 115/148 and PalletSet W (up to 40kg transfer weight) has a range of 1600mm. While the machine is doing productive work, further workpieces can be set up for machining. A central set-up station with the EROWA Lift facilitates the operator s day-to-day work to a considerable extent. Work really becomes enjoyable once the machine and the Robot are controlled through the EROWA JMS 4.0 process control system. The JMS 4.0 provides the machine operator with all the latest relevant information and various planning aids online at all times.

Minitend, which is the standard machine feeding system, is a robotic automation system that reduces labor costs by up to 90% and increases production numbers by up to 60%. The simplicity of Minitend s design is reflected in its ease of use. Within minutes, a new part can be adapted and unmanned operation can be started. User-friendly, compact and accessible, Minitend is the simplest loading solution you can come across with these features. Minitend, which is a standard machine feeding system, allows feeding more than one machine.

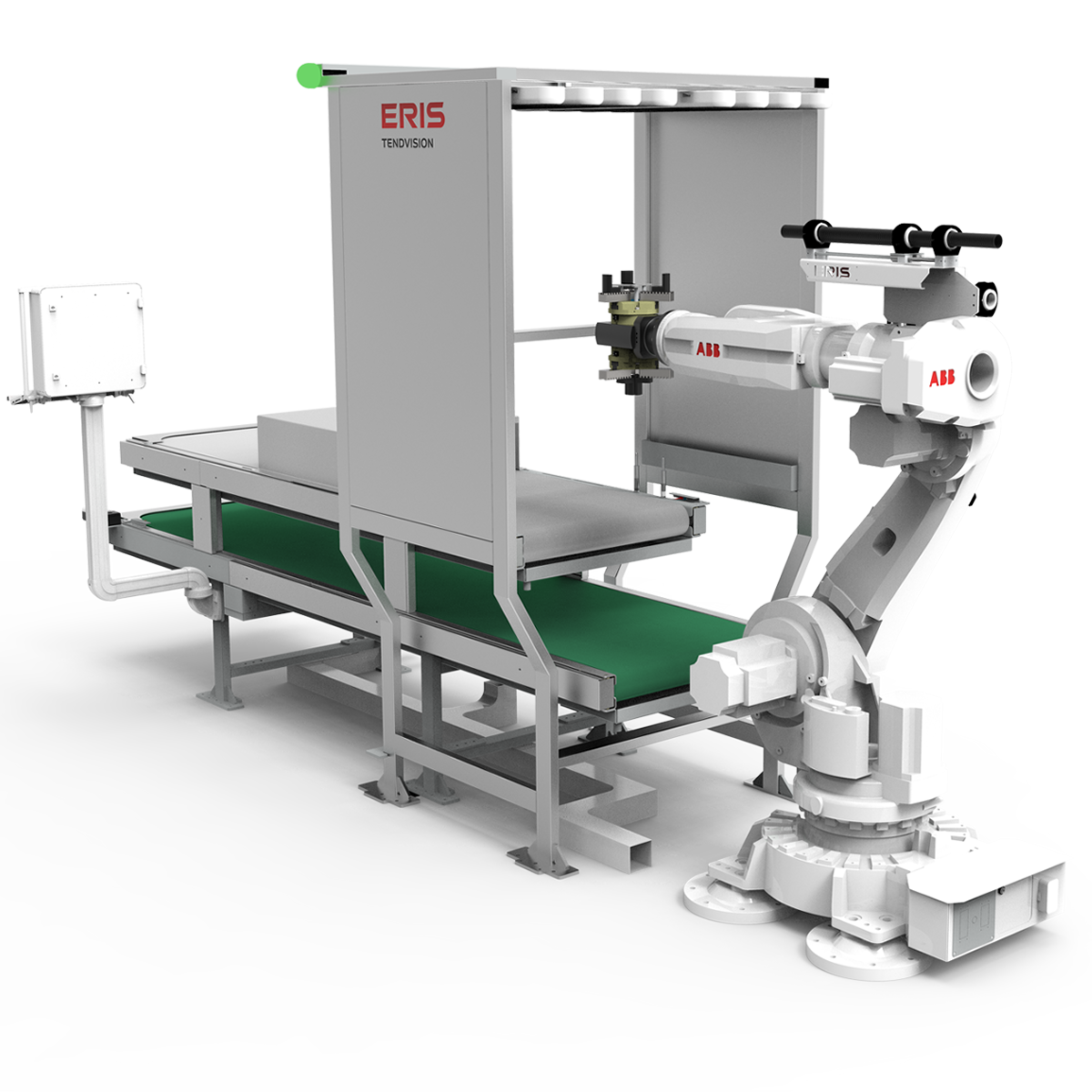

Tendvision is the smart machine feeding solution. in different parts mechanical adjustment is eliminated to simplify operation. has been removed. Loading and unloading conveyors to your place in the factory can be easily designed accordingly. The system can balance all kinds of workpieces on its own. It can feed any kind of machine. With the development of technology, the change in machine tools Tendvision, for flexible and cost-effective production standardized to meet increasing requirements.

Ringloader is the ideal feeding system solution for parts with low height. It allows the operator to decrease the frequency of coming to the counter up to once per shift. provides. The system is designed for lathes and gear benches. Adjusting parts of different diameters is just one with the adjustment lever. It does not require fixtures or apparatus. Ringloader has different models according to workpiece dimensions. In this series, more than one CNC can be fed if the same part is processed.

With Minitend-L, you can load spindle type parts up to 1150 mm, exceeding the limit in production.

- ERIS

TR

TR